Vidarr

Unlocking sour production chemical-free H₂S removal.

-

Lower Costs

Reduce or eliminate the need for costly chemical treatments with mechanical gas removal.

-

Easy Integration

Skid-mounted design means fast setup with minimal site work — no major construction required.

-

Cleaner Operations

Strip H₂S and VOCs without harmful additives, helping meet environmental and safety goals.

Skid-Mounted. Chemical-Free. Cost-Effective.

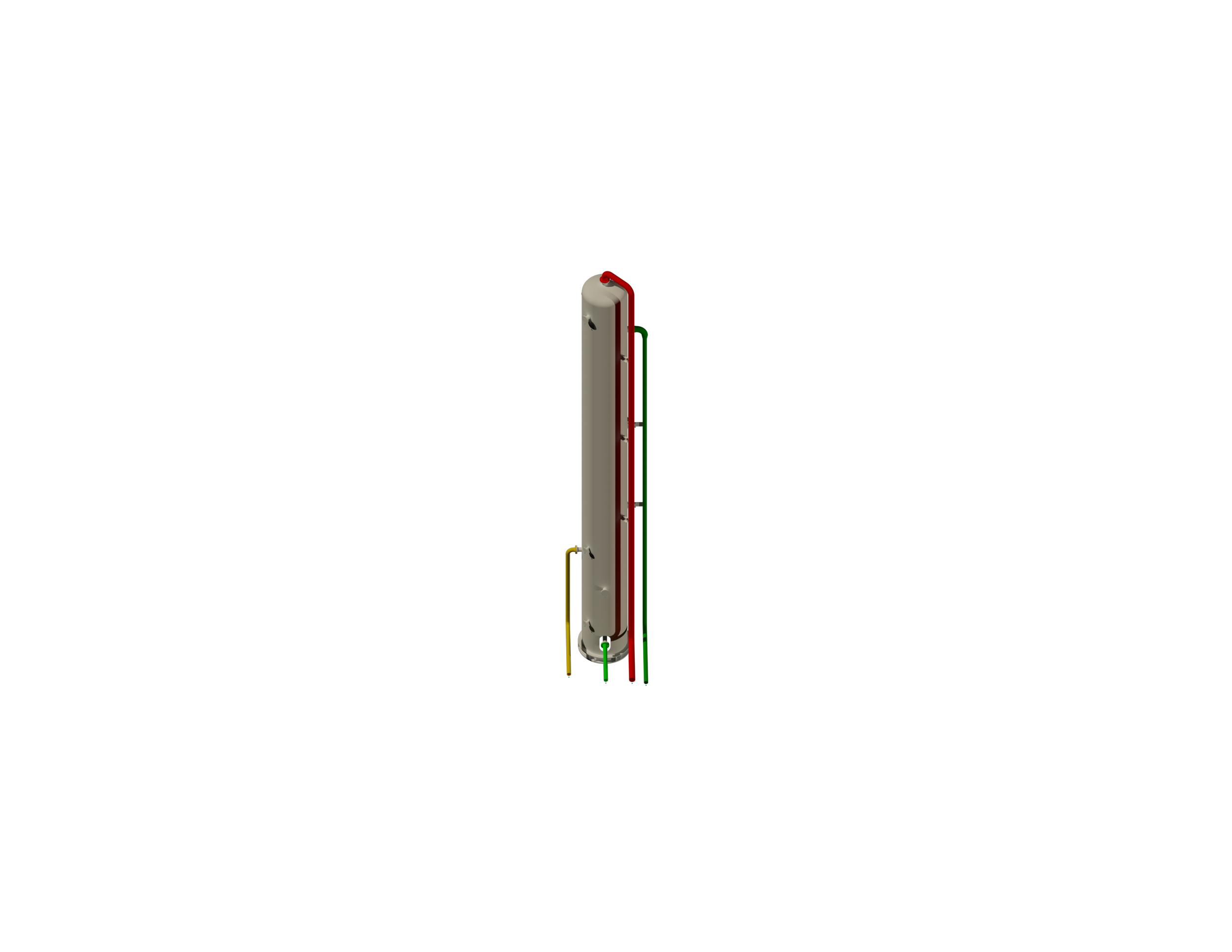

The VIDARR Contact Tower

A skid-mounted contact tower that mechanically strips H₂S and VOCs from crude oil — reducing chemical use, protecting equipment, and increasing the value of sour production.

Easy to integrate and scalable, VIDARR offers a safer, more efficient way to stabilize sour oil streams.

HOW IT WORKS

VIDARR uses mechanical gas stripping — not chemicals — to remove H₂S and VOCs inside a contact tower.

The result? Cleaner, stabilized crude oil that meets industry standards, with lower costs and consistent performance.

Unlocking Permian Sour Production

The Permian Basin holds large reserves of H₂S-rich crude. Traditional treatment relies on expensive, hazardous chemicals.

VIDARR gives producers a safer, more economical way to tap into this resource — without the chemical burden.

Why Choose VIDARR?

Reduces chemical dependency by lowering operational costs

Aids in preventing equipment fouling and corrosion

Improves crude oil quality by reducing VOCs

Enhances safety by reducing exposure to hazardous gases (removal of H2S)

Requirements

Operates with minimal sweet gas and compression, making it easy to integrate into existing operations.